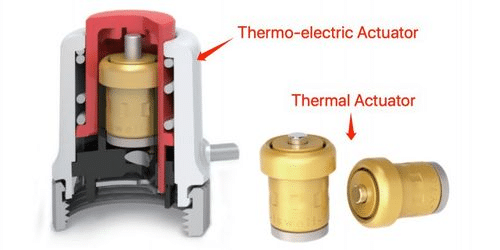

The TWA (Thermal wax actuator) is a small actuator for electrical on/off controls to activate several types of valves and floor heating manifolds.

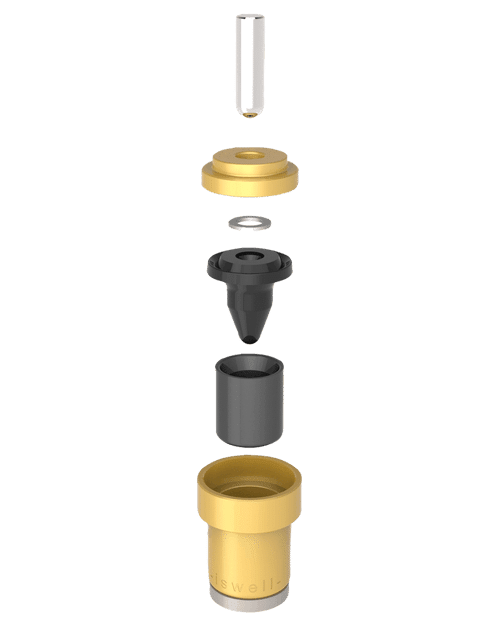

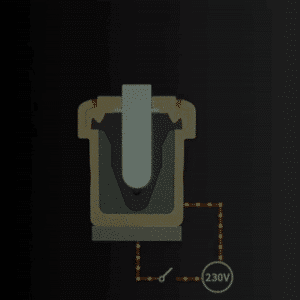

The thermal actuator is a compact actuator that converts electric/thermal energy to linear mechanical motion by taking advantage of the outstanding expansion characteristic of the wax as it transforms from the solid phase to the liquid phase.

Thermo-electric Actuators are very common in underfloor heating systems, radiators, fan coils, and other applications where the remote ON/OFF control of hot and cold fluids is required.

The actuator is equipped with a visual position indicator to show the open or closed position of the valve.

The TWA range covers actuators for 24 V SELV (Separated Extra Low Voltage) or 230 V supply in both NC (normally closed) or NO (normally open)versions (valve positions with no supply voltage to the actuator), and the 24 V TWA for RA valves also comes in a NC/S-version with an end-switch.

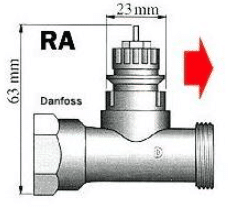

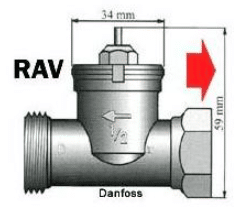

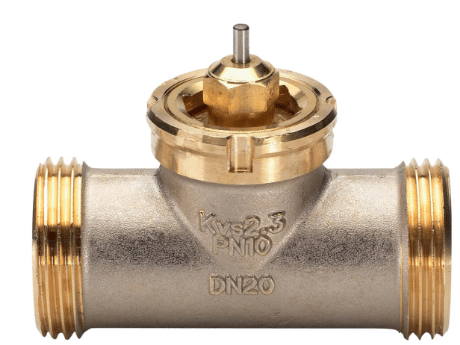

The TWA can be connected to the RA (Raised faced), RTD, RAVL, and RAV valves from Danfoss. Furthermore, versions for valves with Heimeier/MNG/Oventrop M30×1.5 connection are available. Other valves must be verified individually to ensure correct valve closing measurement and valve top geometry.

K valve (M30x1.5)

RA valve (23 mm)

RAV valve (34 mm)

RAVL valve (26 mm)

RTD valve

VMT valve

Working Principle of a Thermal Actuator

The wax volume responds to temperature changes much more significantly than other common substances. The temperature-sensitive wax is the basis of a thermal actuator. It must be precisely proportioned and evenly mixed.

Here is the working principle of a thermal actuator, step by step

1) The temperature starts rising when the PTC powers on

2) The solid wax inside the brass housing starts to melt and expand as the temperature gets closer to the melting point

3) As the space inside the brass housing is unchanged, the volume expansion of wax keeps squeezing the “elastomer bag”

4) The “elastomer bag” pushes the piston out as there is less and less space left in the “bag”

Share this content: